PASCACK VALLEY—This is excerpted from an article that originally appeared in the Pascack Historical Society’s quarterly publication, Relics.

Before the days of refrigeration, quite a bit of planning and hard work went into ensuring an adequate supply of ice in the summer months. Blocks of ice harvested in the winter would be stored through spring and then delivered to houses, via horse and wagon, for customers to put in ice boxes to keep their food cold. Many years ago, ice harvesting was a very important business.

There were many local ice houses, and these were usually square buildings with 8-inch-thick walls. For insulation, they were filled with sawdust from the mills. They were built with small doors all the way down the side, each layer of ice having its own door for removal. In the winter, folks cut thick chunks of ice from the Musquapsink and Pascack brooks, as well as back ponds (formed by man-made dams in the brooks) and stored them in these ice houses for use in the summer.

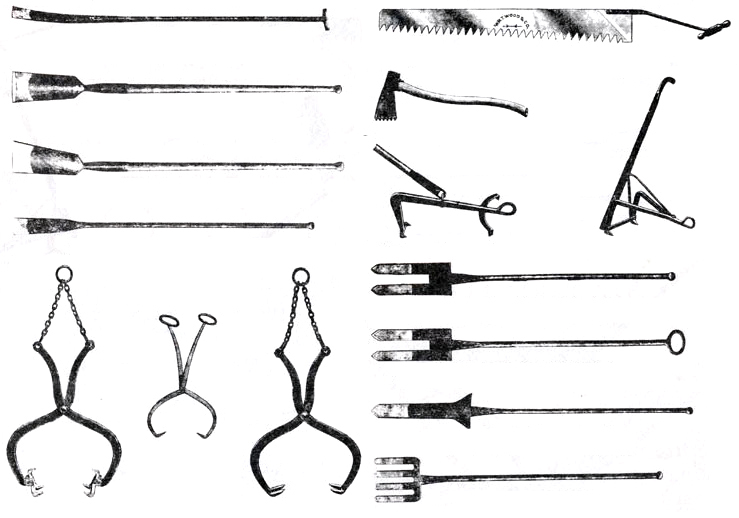

It was a bit of a gamble to wait for thick ice and take a chance on having warm weather set in. One hoped for 14 inches, was happy with 12, and would settle for 8 or even 6. When the decision was made to cut, the first step after clearing away the snow was to etch straight lines in two directions on the frozen pond. Then a special horse-drawn plow was employed to cut grooves in the ice along those lines. An outrigger on the plow helped keep the lines parallel by using the previous groove as a guide. Thus, the pond would be marked into a grid of squares, each one representing an ice block to be cut.

The first ice had to be removed with a saw, but succeeding blocks were cracked off the ice sheet using a heavy steel bar with a chisel edge. Dropped sharply into the groove, it would cause a fairly clean break through the thickness of the ice. A worker would use a pointed pole to push the ice block to a chute leading to the ice house. Horse power was again used, this time to raise the block into its storage spot using a rope and pulley system.

When the warm weather arrived and the ice supply was needed, a door of the ice house was opened and a cake of ice extracted from the sawdust. It was then loaded onto a wagon, together with tongs for handling, a scale for determining how much to charge, and an ice pick for fitting the delivery to the space available in each customer’s ice box. Most people used ice boxes until electric refrigerators became more affordable and reliable starting in the 1930s.